Product

A Tank Jacking Systems & Equipment

1 Astha Hydraulic Tank Lifting Jack Mode

The time for lifting a shell plate up to 2.5 meters in height is as follows:

Using double-acting jacks – 45minutes

Using single-acting jacks – 3-3.5 hours

Double Acting Jacks work 5 times faster than Single Acting Jacks

|

Model / Description |

AIEIPL – HTJE-12 MT- SA |

AIEIPL – HTJE-12 MT- DA |

AIEIPL – HTJE- 18 MT-DA |

AIEIPL – HTJE- 25 MT-DA |

|---|---|---|---|---|

|

Working Capacity (Metric tons) |

12 |

12 |

18 |

25 |

|

Testing load (metric tons) |

18 |

18 |

27 |

37.5 |

|

Standard arc distance between jacks (m) |

2 to 3 |

|||

|

Max Shell plate lifting height |

2.5 or 3 or more |

|||

|

Min shell plate lifting height |

0.80 |

|||

|

Min safe bearing capacity below trestle base plate (N/mm2) |

1.45 |

|||

|

Plate thickness range (mm) |

6 and above |

6 and above |

||

|

Unitary climb (mm/stroke) |

100 |

|||

|

Time per stroke (minutes) |

10 |

1 to 1.55 |

||

|

Working pressure (kg/cm2) |

120 |

142 |

160 |

|

|

Piston retracting system |

Spring |

Hydraulic Pressure |

||

|

Trestle retractable system to allow internal welds using an automatic girth welding machine |

No |

No |

No |

No |

|

Also, order example |

||||

|

Model No. |

AIEIPL- HTJE-12MT-SA = Single Acting Jack 12-ton capacity AIEIPL- HTJE-12MT-DA = Double Acting Jack 12-ton capacity AIEIPL- HTJE-18MT-DA = Double Acting Jack 18-ton capacity AIEIPL- HTJE-25MT-DA = Double Acting Jack 25-ton capacity |

|||

|

Maximum shell lifting height |

A = 2500 mm B = 3000 mm |

|||

|

Type of Contact with shell plate |

J = Lifting J-hooks: no welding of lifting cleats to tank shell plate. L = Lifting Non-Welded Arm: cleats to be welded to the tank shell plate. |

|||

|

Retractable Tank jacking system |

RT = enables internal welding using an automatic girth welding machine. |

|||

|

Example: AIEIPL-HTJE-12MT-DA-A-J-RT: Double acting jack 12-ton capacity suitable for 2500 mm width shell plate with lifting J-hooks and with retractable arrangement. |

||||

2 Astha Tank Jacking system without welding to shell plate (tank)

Hydraulic Tank Jacks Model AIEIPL-HTJE-12MT-DA-A-J-RT (“J” = J-Hooks)

These hydraulic tank jacks come with “Tank lifting J-hooks” instead of a lifting arm. The J-hooks hold and lift the tank shell plate from the bottom edge of the shell plate. Welding of lifting lugs and fend-off lugs is eliminated and there is no need to test and repair of tank shell plates after removing the lugs.

Hydraulic Jacking equipment with lifting J-hooks is denoted by the “J” in Model No. The procedure for fixing the next shell course and removal of J- hooks is explained below:

The tank is lowered down using hydraulic jacks and rests on the newly erected tank shell plate ring keeping a root gap as per WPS. To do this, the hydraulic jacks are lowered down by around 60 mm, and extra heavy support is fixed to connect the tank with the new shell ring. Released hydraulic jack from shell course, J- the hooks are locked with shell plate, pull the J-hooks down side by pulling machine or chain block.

3 Astha Retractable Hydraulic Tank Jacking Systems

Once the tank is lifted using our jacking equipment, and a new course (shell ring) is placed, vertical and horizontal welds are completed either manually or using an automatic welding machine. Root welding can be done either manually or using a few attachments of our Automatic Girth Welding head using backing strip material. After external welding, hydraulic jacks are released from the tank shell plate, lifting lugs and fend-off lugs are removed, and with the same hydraulic power pack (which is used for lifting jacks), all trestles box retracts away from the tank shell, to allow for space for the use of the Astha Group of company SAW single side AGW for internal welding, the welding process is very fast. After the internal horizontal welding is done, the trestles box is moved back by the same power pack to its original vertical position, ready to lift the next shell course

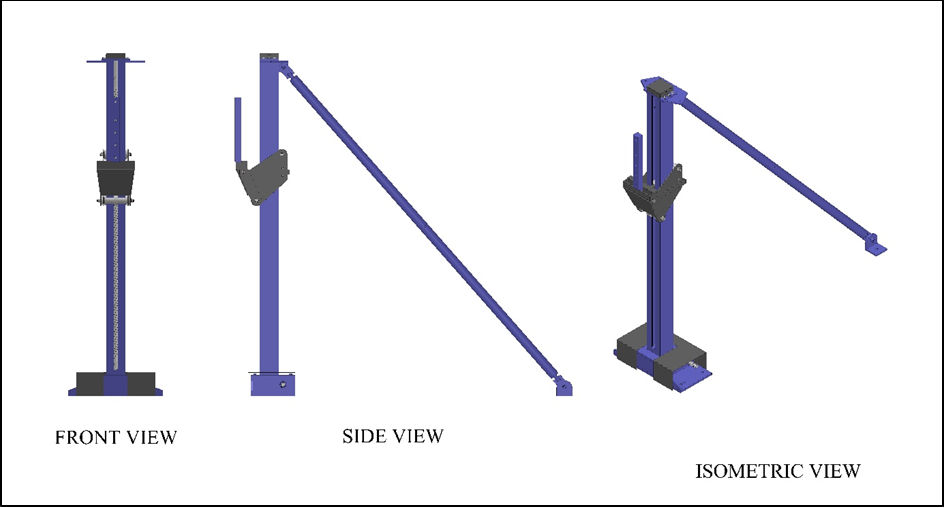

4 Mechanical Screw Jack For Bolted Tank & Grain Silo

A screw Mechanical jack is used for Erection of GLS steel Bolted Tanks & Grain Silos. We manufacture different models as below:

Models:

- 3.5 T

- 5 T

- 6.8 T

- 8 T

- 12 T

- 18 T

Different types of tanks can be erected using our Mechanical Tank Jacking Equipment:

- Bolted Silo tank

- GLS Tank

- GFS Tank

There are various applications for our Mechanical Tank Jacks. It can be used for:

- Fabrication of Tanks

- Dismantling of Tanks

- Increase the height of Tanks

- Decrease the height of Tanks

- Relocate Tanks

- Replace Tank Bottoms

- Repair Tank Bottoms

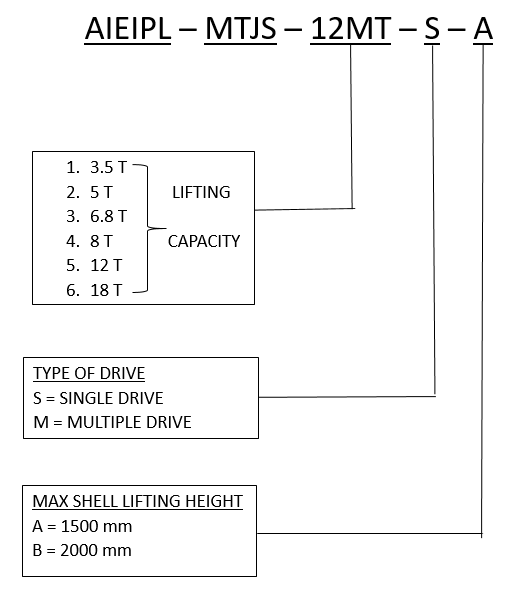

Order Example

5 Astha Jacking System for Tank Repair services

- Replacing tank bottom plates and/or annular plates

- Replacement of lowermost shell course

- Correcting tilt in the tank as a result of foundation settlement

- Replacing cathodic protection, HDPE liner

- Roof repair fixed / dome

- Internal / External Floating roof

- Tank cleaning

- Foundation Repair

- Other Tank accessories replacement/repairing

- Addition of extra shell course to an existing tank

- Preparation of stability calculatio

6 Technical Support

- 3D Design Support on Software (SolidWorks, Ansys, )

- Work Method Statement (WMS)

- Engineering Design Calculation for:

- Lifting load Calculation (shell/ Tank, floating roof)

- Tank Lifting Lug/Cleat

- Temporary Shell / Column / Floating roof Supporting structures

- Wind girder / Stiffener ring (If required)

- Shell Ingress support

- Engineering Drawing for

- General jack layout with tabular data

- Annular / Bottom plate layout with cutting plan

- Annular / Bottom welding sequence

- Shell Ingress / Door cutting layout with stiffener supports

- Temporary supporting structures fabrication drawing

- On-site Technical core team for Tank Bottom Plate Replacement

- Tank Hydro Testing

7 Comparison

Astha Jacking Method Is More Excellent Than Traditional Method for Field Erected Tanks

Comparison between the traditional method and the jacking method

Large vertical storage tanks generally refer to storage tanks whose diameter is more than 5 meters, especially those whose maximum diameter can be up to 40m-50m and whose maximum height can be up to more than 10 meters. For the fabrication and installation of this kind of large storage tank, as it is unachievable to transport an assembled tank, field erection is the most common method. There are several erection methods for field-erected tanks, such as the traditional method, jacking method, and integral lifting after the site prefabrication.

The traditional method is erecting on a ground base of a storage tank, after one section is assembled, the scaffold tower will be added a layer as the tank increases, because of the high operation, and this method is more dangerous.

The jacking method is erecting the tank starting from the roof of a tank on the ground, after one section is installed, the tank will be lifted to the next height by cranes and then installed in the next section.

This assembly method has the advantages of convenient erection, fast progress, production safety, etc.; therefore, it has been widely used all over the world.

B Astha Tank Welding Equipment

1 Automatic Girth Welding Machine

Submerged Arc Automatic Girth Welding (AGW) machine for Single Side Welding suitable for horizontal welding of tanks

built “TOP-DOWN”.

SAW welding power source is IGBT based, 1250 Amper with constant voltage characteristics with step-less control

Mounted on 4 wheels.

|

Model |

AIEIPL-SAW-AGW-HW-CM |

|---|---|

|

Input supply |

3 phase 415 Vac +/- 10% |

|

Welding Plate Width |

For first/top shell – min. 800mm For subsequent shells –No restriction |

|

Class of insulation |

H |

|

Transformer |

Cupper |

|

Display (A / V) |

Digital meter on panel |

|

Tank Diameter |

Suitable for tanks Diameter of more than 8 meter |

|

Welding Current |

From 200 – 1000 Amps at 100% duty cycle |

|

Output Voltage |

44Vdc |

|

Welding Speed |

250 mm to 700 mm/min |

|

Idle Travel Speed |

Upto 1000 mm per minute |

|

Wire Diameter |

2.4mm/3.2mm/4mm/5mm |

|

Weight of Welding Head |

216 Kgs (approx.) without flux & wire spool |

|

Auto Flux Recovery Unit |

Inbuilt |

|

Flux Heater |

Inbuilt |

Features:

- Weatherproof Electrical cabinet.

- Robust DC motor for tractor movement.

- Fine adjustable manual cross slide for vertical & horizontal adjustment.

- Weld head slide assembly.

- Flux stored in Flux Recovery Unit as well as in Flux discharge hopper.

- View glass in flux hopper & in Flux Recovery Unit

- Same Power Source can be used for root welds and for FCAW / MIG / SMAW vertical welds.

- Two or more FCAW / MIG / SMAW welding heads can be used using one Power Source (by using Multi weld 350) which increases vertical welding productivity by more than double.

- Auto flux recovery unit.

- Auto sensor for wire feeder speed.

- Same mechanism can be used for Arc gouging.

- Ambient temperature range at which the machine can work: -5 to + 65 deg C.

- Machine is compact, lightweight & can be handled without the need for a large crane.

- Root welding with backing strip possible

- Astha AGW does the work equivalent to 6 welders

2 Tractor for bottom plate welding

The welding Tractor is a self-propelled mechanized wire feeder, designed for the submerged arc process. It is self-guiding.

Its compact size fits through small openings and confined spaces. Butt and fillet welds can be made on heavy plates or steel

as thin as 2.5mm.

The tractor is used for:

Tank bottom plate welding

Shell to annular plate welding from inside the tank

Shell to annular plate welding from outside the tank (magnetic rollers provided)

TECHNICAL SPECIFICATION:

Welding Speed mm/min : 120 – 1600

Wire diameter mm : 2.4/3.2/4/5/6

Weight of Tractor : 45 Kg (without flux and spool)

Nozzle Vertical adjustment : 100 mm

Weld angle : 450

Wire feed range m /mm : 0.25 – 2.5

C Astha Tank Lifting Jacks Applications

Hydraulic Telescopic Jacks for Steel Bolted tanks & Grain silo

Astha Group of a company is manufactures and rents hydraulic telescopic jacks of 3.5 tons, 5.6 tons, 6.8 tons, and 7.5ton

capacity suitable to lift up to 2500 mm. These jacks find use in the erection of bolted or welded tanks for storing water or

other bulk liquids or powders